From beans to machines, we can help with all your coffee needs.

Join a coffee plan

Sign up to a regluar delivery of coffee capsules, straight through your letterbox.

Start here →Beans

Beans

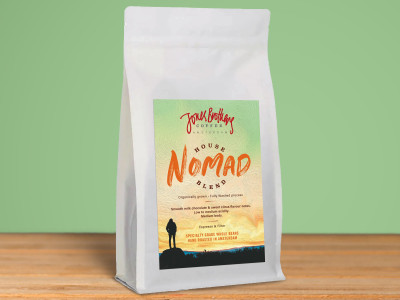

Whole coffee beans, sustainably sourced, 100% Arabica.

M*lks

M*lks

Plant-based milk alternatives to compliment your coffee.

Gear

Gear

Great accessories to improve your coffee experience.

Moccamaster

Moccamaster

Expert coffee machine for your home.

When is the harvesting time for coffee beans?

Harvest time is an important economic time for the farmers and the pickers. Read more below.

In May and June we are about to enter into the harvest time for one of the world’s biggest producers and exporters of Coffee – Brazil. The months from end of May through to end of September are critical in determining the worldwide price of coffee beans such is the scale of production in Brazil. Everyone is waiting and wondering what bounty there will be from this year’s crop. Has there been too much or too little rain? Are the crops ready and ripened at the right time?

Most other countries in Africa and other parts of South and Central America generally harvest between November and February or March. In most coffee-growing countries, there is one major harvest a year, though in countries like Colombia and Kenya, where there are two flowerings a year, there is a main and secondary crop.

Harvest time is an important economic time for the farmers and the pickers.

Due to the particular characteristics of the coffee tree and the fact that coffee is often grown in mountainous areas, most of the ripe coffee cherries are usually picked by hand (“selective picking”), a labour-intensive and difficult process. This is when the fields and mountain-sides will swarm with pickers with heavy baskets. The main exception is Brazil, where the relatively flat landscape and immense size of the coffee fields means that a lot of the picking is done by machine (“strip picking”). But it can lead to lower quality as all cherries are picked whether ripe or not. In general, most Arabica is hand-picked due to the mountainous regions it grows best in and because of its higher value.

Getting the right quality is key and for this the best cherry is a ripe cherry. Not all coffee cherries ripen at the same time so the coffee trees will need to be harvested a few times to allow all the cherries to ripen. But there is a narrow window of 10-14 days when the cherries could over-ripen. Each tree will yield an average of 2 to 4 kilos of cherries and a good picker can harvest 100 to 200 pounds of coffee cherry a day, which will produce 20 to 40 pounds of coffee beans. At the end of the day, each worker’s harvest is carefully weighed and each picker is paid on the merit of his or her work. The day’s harvest is then combined and transported to the processing plant.

Psss...Discover here our range of 100% Arabica coffees, dark and medium roasted, natural and washed process, from origins like Ethiopia, Thailand, Guatemala, Colombia, Nicaragua, Brazil, Indonesia, Peru, etc.

How are the beans processed?

The age-old method of processing coffee, which is still used in many countries, is known as ‘dry milling’ where water resources are limited. The freshly picked cherries are simply spread out on huge surfaces to dry in the sun or by special drying machines until they have a designated humidity level of 10-12%.

‘Wet milling’ is now the preferred form of processing. This method is more complex than dry milling, but it tends to produce a higher quality bean. Wet milling begins with the harvest. On the same day as the harvesting, the cherries are transported to a pulping machine that removes the outer skins. The beans are then dried or sent to fermentation tanks where they are left to ferment. Once this process is finished, the beans are washed thoroughly with clean water to remove any residue. After washing, they are dried in the sun or by artificial drying machines. The end product is a ‘green bean’- a coffee bean that is still raw and unroasted. Coffee beans need some love and care and must be allowed to “rest” in their outer parchment layer for 30-60 days at least after drying with good ventilation to prevent any moisture forming on the outer skin.

These beans will now be even more precisely sorted by size and weight. They will also be closely evaluated for colour flaws or other imperfections. Typically, the bean size is represented on a scale of 10 to 20 to describe a ‘screen size’. All of these factors contribute to and determine the end price this coffee can realise.

Phew…after all this washing, drying, sorting and storing…our humble bean is ready for export. Next time…a focus on quality and grading the beans.

Love what we brew!

The Bean Team